| Variant | Art.-No. 536887 | fischer Concrete Screw FBS II 10x100 45/35/15 SK countersunk head | ||

| ETA-approval | ||||

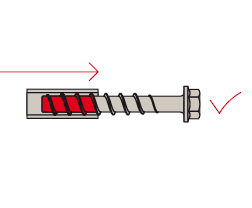

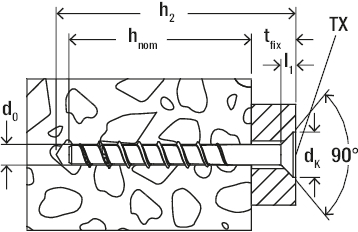

| Drill diameter | 10 | [mm] | ||

| Screw | 12x120 | [mm] | ||

| Screw-in depth with fixture thickness | 85/15 | [mm] | ||

| Drive | TX50 | |||

| Packaging | Folding-box | |||

| Quantity/pack | 50 | [St.] | ||

| GTIN (EAN-Code) | 4048962251708 | |||

| Price / Pack | 8260.00 ₹ | |||

Product Description

Application and Permission

Approved for:

* You can find detailed information on building materials in the registration document.

Permission

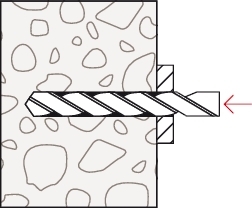

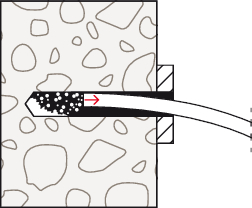

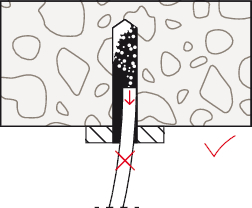

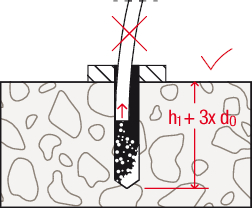

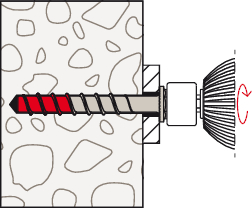

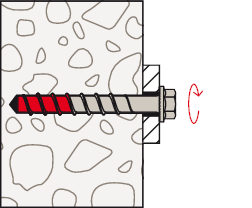

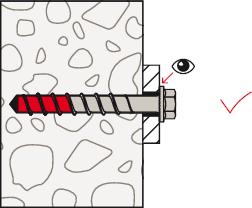

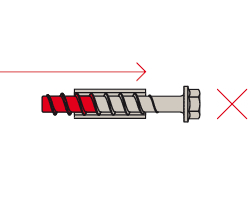

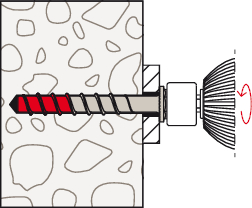

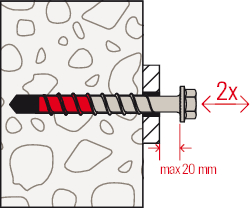

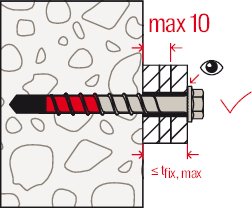

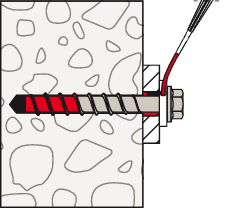

Assembly Instruction

Technical Data

Technical Data

| ETA-approval | |||

| Drill diameter | 10 | [mm] | |

| Screw | 12x120 | [mm] | |

| Screw-in depth with fixture thickness | 85/15 | [mm] | |

| Drive | TX50 | ||

| Packaging | Folding-box | ||

| Quantity/pack | 50 | [St.] | |

| GTIN (EAN-Code) | 4048962251708 |

Documents for Downloading

Additional Documents

Approvals

| Title | Type | Created | Valid Till |

|---|---|---|---|

| Title ETA - European Technical Assessment (PDF, 5 MB) European Technical Assessment for fischer concrete screw ULTRACUT FBS II | Type | Created 05-10-2020 | Valid Till |

| Title DOP - Declaration of Performance (PDF, 3 MB) | Type DoP 0184 | Created 28-04-2020 | Valid Till |

| Title DOP - Declaration of Performance (PDF, 2 MB) | Type DoP No. 0078 | Created 19-04-2016 | Valid Till |

| Title DOP - Declaration of Performance (PDF, 3 MB) | Type DoP No. 0146 | Created 06-11-2018 | Valid Till |

| Title DIBt, National German Approval (PDF, 1 MB) | Type Z-21.8-2049 | Created 13-07-2016 | Valid Till 13-07-2021 |